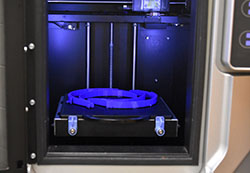

They are 3D printers, one as large as a full-size refrigerator, and they are producing visor pieces that will be attached to transparent face shields. The finished products are being given to area frontline healthcare providers as they and their colleagues across the world continue to come to grips with the ongoing COVID-19 crisis.

A 3D printer creates a physical object from a three-dimensional digital model by laying down several thin layers of a plastic-like material in succession.

Frey said the first design she started using came from the Nucor Detailing Center.

“They modified the design from a company called Prusa to work for their printers. I am printing these type of visor pieces in conjunction with Nucor. The other design I’m using from Stratasys, the manufacturer of our 3D printers, prints much faster, taking about a half-hour off the print time.”

The Prusa-designed visors have notches that allow for a protective film shield to be attached to them, while Stratasys-designed visors secure the face shield to them with an elastic band. The Prusa devices will be given to Faith Regional Health Services in Norfolk. Other healthcare providers across the 20 counties in Northeast’s service area will be provided the additional visors.

Frey began pursuing printing of the visor pieces after reading a number of articles on the shortage of PPE (personal protective equipment) in hospitals across the country. Some of her colleagues on LinkedIn said they were printing facemasks where they used materials such as vacuum cleaner bags to serve as the filter on the masks. That got her to thinking about using the 3-D printers in her drafting lab to help, too.

“I spoke with Wade Herley (dean of business and technology at Northeast) about whether we could do something similar. We started having those conversations a couple of weeks ago after we heard that two engineers in Italy started printing ventilator valves since our printers could do that as well. They contain the internal details that are required for that level of a 3-D print.”

Frey then learned that Nucor started printing the visor pieces for first-line healthcare providers and joined in the effort to print additional visors.

The material, or filament, used to create the visor pieces is called ABS (Acrylonitrile Butadiene Styrene) – a type of plastic that is used on industrial 3D printers. Some of newer printers are using Polylactic Acid, commonly known as PLA, which is made from corn. It can be printed at a low temperature and does not require a heated bed.

The two printers being used now at Northeast in Norfolk are described as fused deposition modelers. Frey said the best description for how they work is similar to a hot glue gun.

“The filament feeds up through the machine while the nozzle is heated up. It then pushes the filament through the hot nozzle and down to a .010” diameter. It basically draws the outline of your part on the tray and colors it in with a bead of plastic. It builds one layer at a time.”

When it comes down to it, Frey said it is a fairly simple process.

“The inventor of the 3D printing process just duct taped a hot glue gun to a CNC (computer numerical control) machine to come up with the concept of fused deposition modeling technology,” Frey said.

While Frey used the .010” measurement on the Prusa visors, she did turn up the measurement to .013” on the Stratasys models in order to get them out at a faster pace.

Northeast has another 3D printer in the drafting lab, known as a Stereolithography printer. It uses a liquid resin which allows each layer to be cured by a laser. It allows for a higher resolution, however, the support material is not soluble. It could be used to produce other medical parts should the need arise.

The two printers in use at the College can produce 36 of the Stratasys models a day or four of the Prusa models every three hours. The Prusa-designed visors from Northeast go to Nucor where they are assembled while Frey assembles the Stratasys-designed visors.

She considered printing masks made of material with ABS, but she said they take much more time to produce. The process would involve cutting up an N95 mask or use some of the college’s material for the filter.

Northeast Community College in South Sioux City is also beginning work to produce 3D printed pieces that will be provided to a Sioux City, IA, hospital.

Biology Instructor Amanda Thomason began working with Frey after UnityPoint Health reached out to the community for more PPE. She said the hospital put out the call for anyone with 3-D printers to assist in making earpieces and visors.

Thomason is pleased to help Siouxland healthcare workers who are on the front lines of the pandemic.

“I personally know many healthcare providers and the little amount of PPE they currently have is heartbreaking. I want to help out in any way possible as these are the people who work countless hours to help and protect their patients, while we need to also step up and help protect them,” she said. “I am grateful that we are coming together as a community, more than ever before, and helping our providers get the visors, earpieces, masks, and other PPE that they desperately need at this time.”

Frey concurred. She said she is pleased that Northeast Community College is able to assist to meet the need for this type of PPE.

“I am not in any way involved in the healthcare industry, so this is my way to be involved. I hope it’s helping the people who really need them.”

--###--

PHOTO CUTLINE