NORFOLK, NE - When the blade on a small fan breaks, it usually can be repaired, replaced or disposed of. But what happens if the blade happens to be nearly 30 feet in length? That’s when you call in the experts and allow students learning to be future industry professionals work side-by-side with them.

A team from RENEW Energy Maintenance, of Sioux Falls, SD, was on the Northeast campus recently to change out the three blades on the College’s Micon 108 wind turbine. Originally, one of the blades had some damage on the “root” end that bolts onto the turbine.

However, John Liewer, wind energy technology instructor, said the turbine’s blades were replaced because all three need to be balanced. He said it is crucial that each blade’s weight is distributed evenly at the “root as well as at the tip.”

“We did not have the data on the other blades, so we would have had to take all three down, measure the weight of the other two, adjust the replacement to match, and then replace them. We determined it would be more cost effective to get a matching set and start from scratch.”

Although it stands 80-feet to the hub, the Micon 108 is approximately 170-feet shorter than a standard commercial wind turbine. However, the same risks exist when it comes to maintenance.

“There are still moving parts. There are still fall hazards and drops hazards,” said Josh Ackerman, specialty service manager for RENEW Energy Maintenance. “So that’s always a challenge no matter what we do, but it’s still a little different. It was actually a breath of fresh air to see something a little smaller, because it was like, ‘Oh, we don’t have to climb all that 250-300 feet.’ But the general idea is that it’s same as any other tower.”

The work took the use of a 45-ton boom truck from Pro Crane in Norfolk, which allowed the crew to pull the blade straight up and then down to the ground. The work of changing blades on a larger turbine would require the use of two cranes and each blade would be removed and replaced sideways, according to Ackerman.

The RENEW crew enjoyed working with the Northeast wind energy technology students. Ackerman said they appreciated their help.

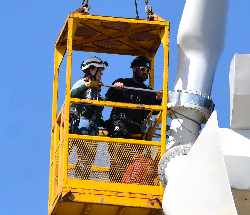

“The students have been real hands-on today. They have been asking a lot of questions and trying to get in, so that’s been cool. I have offered all of them rides up and down in the basket.”

“We have tried to get as many of them as we could to the top of the tower to see how that’s going. They have seemed to have liked it. It couldn’t have gone better.”

Wind energy technology students participating in the work included Ryan Colsden, of Stanton, Brent Freudenburg, of Norfolk, John Honrath, of O’Neill, Rebecca Kriss, of Comstock, and Zach Schindler, of Norfolk.

Liewer said the students were very excited to get to play such an active role in the project. He said all of them rearranged their schedules to volunteer to come in.

“RENEW Energy Maintenance was very gracious to involve these students to the degree that they did. For the students, it was a great precursor to the internships that they will complete this summer. They will be working in this type of environment every day. Their experiences on this particular day rejuvenated their enthusiasm for the career they are pursuing.”

To see Pro Crane’s aerial footage of the work on the Northeast Community College wind turbine, go online to You Tube at https://youtu.be/3UbJ6kMT7i4.

--###--

PHOTO CUTLINE

Northeast Community College Wind Energy Technology student Rebecca Kriss, of Comstock, assists Josh Ackerman, specialty service manager for RENEW Energy Maintenance, of Sioux Falls, SD, tighten bolts on the College’s Micon 108 wind turbine on the Norfolk campus recently.